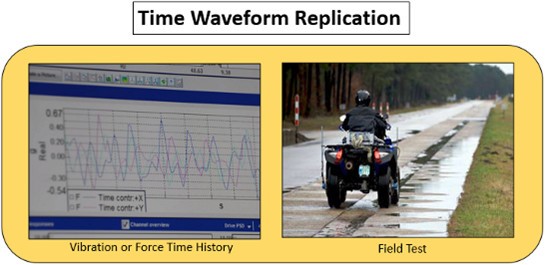

MIL-STD-810G Test Method 525 – Time Waveform Replication

Replication of a time trace under Time Waveform Replication (TWR) methodology in the laboratory is performed to:

a. Provide a degree of confidence that the materiel can structurally and functionally withstand the measured or analytically specified test time trace(s) to which the materiel is likely to be exposed in the operational field environment.

b. Experimentally estimate the materiel’s fragility level in relation to form, level, duration, or repeated application of the test time trace(s).

This test method discusses TWR from a single-exciter/single-axis (SESA) perspective. Although much of the philosophy and terminology in TWR testing is common between SESA, multiple-exciter/single-axis (MESA), and, multiple-exciter/multiple-axis (MEMA), this method will be limited to SESA testing. Multiple-exciter TWR applications are addressed in Method 527. This method provides guidelines for developing test tolerance criteria for single-axis TWR testing. Annex A addresses SESA TWR testing by illustration. Annex B provides an overview of post-test analysis tools useful for TWR, in order to verify test tolerance compliance.

Time trace

The general term “time trace” is employed throughout this method in an attempt to capture all of the possibilities of TWR applied in the replication of field-measured (stochastic) or analytically specified (deterministic) environments in the laboratory. The following six forms of time trace are potential candidates for TWR testing.

a. Stationary random Gaussian time trace with arbitrary ASD of arbitrary duration;

b. Stationary random non-Gaussian time trace (for certain forms of non-Gaussian distribution, e.g., local skewness and high kurtosis) with specified ASD of arbitrary duration;

c. Short duration shock time trace;

d. Non-stationary time trace that has a time-varying amplitude, time-varying frequency or both of an intermediate duration (longer than a typical shock time trace);

e. Non-stationary/stationary time trace that is repetitive at fixed period (e.g., gunfire shock);

f. Non-linear form time trace.

For general application, the time trace to be replicated under TWR is of a substantially shorter duration than stationary random environments, and of a longer duration than mechanical shocks.

This method addresses very general time-varying traces not necessarily identifiable with underlying stationary or nonstationary random processes. It is apparent from various vendor TWR hardware/software configurations that the only requirement for the application of Method 525 is the bandlimited character of the time trace for replication, and its compatibility with the bandlimited characteristics of the device (exciter) to be driven with the TWR hardware/software. For example, measured time traces that vary in frequency can be replicated as long as the time trace bandwidth is limited to the overall bandwidth of the exciter control system. Non-Gaussian time traces can be replicated under TWR. All measured time traces can be replicated under TWR, provided they are within the band limit capabilities of the exciter control system to which they are applied for testing purposes.

Procedure

This method includes two basic test procedures:

Procedure I: The SESA replication of a field-measured materiel time trace input/response. The SESA replication of a field-measured time trace representing an input to the materiel or a response of the materiel considers only an un-scaled measured time trace in the laboratory with a single exciter in a single axis or mechanical degree-of-freedom.

Procedure II: The SESA replication of an analytical specified materiel time trace input/response. The SESA replication of an analytically specified time trace representing an input to the materiel or a response of the materiel considers carefully scaled versions of a measured time trace in the laboratory with a single exciter in a single axis or mechanical degree-of-freedom.

Qualification Tests

When a test is intended to show formal compliance with contract requirements, recommend the following definitions:

a. Failure definition. Materiel is deemed to have failed if it suffers permanent deformation or fracture; if any fixed part or assembly loosens; if any moving or movable part of an assembly becomes free or sluggish in operation; if any movable part or control shifts in setting, position or adjustment, and if test item performance does not meet specification requirements while exposed to operational or endurance test levels. Ensure this statement is accompanied by references to appropriate specifications, drawings, and inspection methods.

b. Test completion. A TWR qualification test is complete when all elements of the test item have successfully passed a complete test. When a failure occurs, stop the test, analyze the failure and repair the test item. Continue the test until all fixes have been exposed to a complete test. Qualified elements that fail during extended tests (tests extended beyond LCEP requirements) are not considered failures and can be repaired to allow test completion.

DID YOU KNOW?

PALS Electronics has experts on all subjects of test engineering, mechanical or electronic design, environmental condition engineer, system engineer etc. PALS provides consulting, training, tailoring, test plan, test engineering, test services in all phases of your project. Please feel free if you have any questions or inquiries from https://pals.com.tr/contact