- 2022-02-28 11:18:55

Preface: This article is the 7th article belonging to an article series. You may find the introduction article from following link: https://pals.com.tr/blog/environmental-test-engineering-and-pals-service-article-series-1

We will proceed to elaborate the “Methods” and “Procedure”s of environmental standards of MIL-STD-810 in our article series. Instead of writing down the obvious information already given in the standard, we will be discussing more practical information on product design, features regarding “Equipment Under Test” (EUT), and conducting tests.

Test Method 505.5 – Solar Radiation (Sunshine)

This method is used to evaluate material likely to be exposed to solar radiation during its life cycle in the open in hot climates, and when heating or actinic effects are of concern. This method is valuable in evaluating the effects of direct exposure to sunlight (solar spectrum and energy levels at sea level). Procedure I is useful in determining the temperature increase (over ambient) of materiel caused by solar loading. Although not intended for such, Procedure II may be used to simulate the ultraviolet effect of solar radiation at different locations and altitudes by using various radiation sources that allow reasonable comparison to measurements of these natural solar radiation conditions.

This method has two purposes:

a. To determine the heating effects of direct solar radiation on materiel.

b. To help identify the actinic (photodegradation) effects of direct solar radiation.

Picture: PFA-370-MIL Outdoor Unit And De-ice Controller Inside Solar Radiation Test Chamber For more info: https://pals.com.tr/product/pfa-370-mil

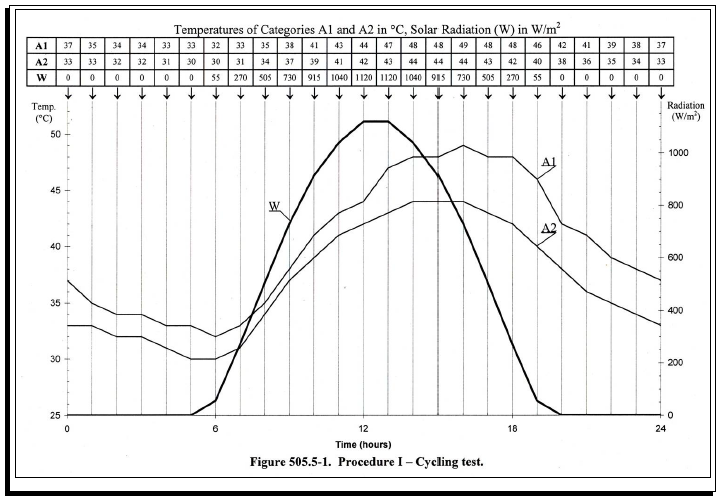

Procedure I – Cycling (heating and/or minimal actinic effects) Use Procedure I to investigate response temperatures when materiel is exposed in the open in realistically hot climates and is expected to perform without degradation during and after exposure. This test was designed to see the heating effect also the actinic effects of solar radiation on materiel in the environment such resembles the natural environment.

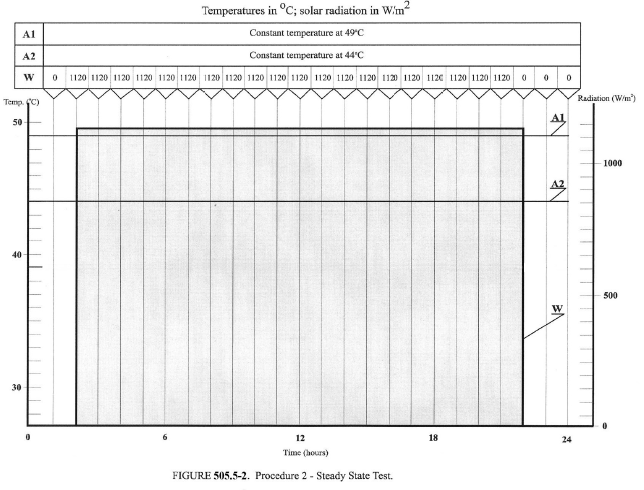

Procedure II – Steady State (actinic effects) Use Procedure II to investigate the effects on materiel of long periods of exposure to sunshine. Actinic effects usually do not occur until material surfaces receive large amounts of sunlight (as well as heat and moisture). Therefore, it is inefficient to use the repeated, long cycles of normal levels of solar radiation (as in Procedure I) to generate actinic effects. Using Procedure I for this purpose could take months. The approach, therefore, is to use an accelerated test that is designed to reduce the time to reproduce cumulative effects of long periods of exposure. In other words, this procedure aims aging effect of sunlight.

Tips and Tricks;

• Please note that the 1120 W/m2 Solar Radiation limit which you may notice on many product’s datasheets is based upon this test’s limits.

• As a rule of thumb tailoring is essential. Meaning choosing a procedure with the customer beforehand.

• Discuss EUT configuration with the customer. Prefer conditions for EUT most likely to be affected in real life. I.e. Storage, Packed, Unpack, Deployed, etc.

• A pyranometer or spectroradiometer to measure the spectral distribution of the radiation imposed on the test item within un-reflective test chambers for large objects. Discus pyranometer placement and position with the customer in this scenario. For test chambers with reflective surfaces usage of a pyranometer is not required; ask your laboratory expert for confirmation.

• Set pass/fail criteria clearly with the customer; which operational features needed to be tested after storage or during tests. Prepare instructions for test laboratory experts step by step about how to test EUT. For example, some devices may be intended to be decomposed or deteriorate after exposure, this may not be a failure criterion. Or in a scenario material paint may damager but a perfect operation of the device may be pass criteria.

• Please note Procedure I requires a change of environmental heat depending on time. This is a high-temperature operational test as well. Reading our previous article about tips and tricks of high-temperature operation tests is highly recommended.

https://pals.com.tr/news/environmental-test-engineering-and-pals-service-article-series-3-mil-std-810g-method-5017-high-temperature

• Please note Procedure II requires a sudden change of environmental heat. Although dissipation of heat will take time, this test soaks EUT on temperature shock. Therefore tips and tricks of temperature shock test are applicable to this test as well. Reading our article is highly recommended.

https://pals.com.tr/blog/environmental-test-engineering-and-pals-service-article-series-4-mil-std-810g-test-method-5034-temperature-shock

• Actinic effect (aging effect) of solar radiation causes deterioration on the exterior of material. Especially on paint. Luckily there are sun reflective or resistant paints are exist.

• Infrared absorbent paints, which are engineered to reduce the thermal signature of the device to make it invisible to heat targeting systems (such as missiles), are also effective against solar radiation because the spectrum also includes infrared wavelength. Therefore reducing the thermal effect of sunlight.

DID YOU KNOW?

PALS Electronics has experts on all subjects of test engineering, mechanical or electronic design, environmental condition engineer, system engineer etc. PALS provides consulting, training, tailoring, test plan, test engineering, test services in all phases of your project. Please feel free if you have any questions or inquiries from https://pals.com.tr/contact