- 2022-02-18 15:27:09

Preface: This article is the 6th article belonging to an article series. You may find the introduction article from following link: https://pals.com.tr/blog/environmental-test-engineering-and-pals-service-article-series-1

We will proceed to elaborate the “Methods” and “Procedure”s of environmental standards of MIL-STD-810 in our article series. Instead of writing down the obvious information already given in the standard, we will be discussing more practical information on product design, features regarding “Equipment Under Test” (EUT), and conducting tests.

Test Method 504.1 – Contamination by Fluids

This method uses contamination by fluids tests to determine if materiel (or material samples) is affected by temporary exposure to contaminating fluids (liquids) such as may be encountered and applied during its life cycle, either occasionally, intermittently, or over extended periods.

Definitions of occurrences by standard are as follows

•Occasionally: Extraordinary/unusual circumstances occurring once or twice a year.

•Intermittently: Regular basis under normal operation; possibly seasonally over the life of the materiel.

•Long periods such that materiel is thoroughly exposed.

Procedures of this method are as follows:

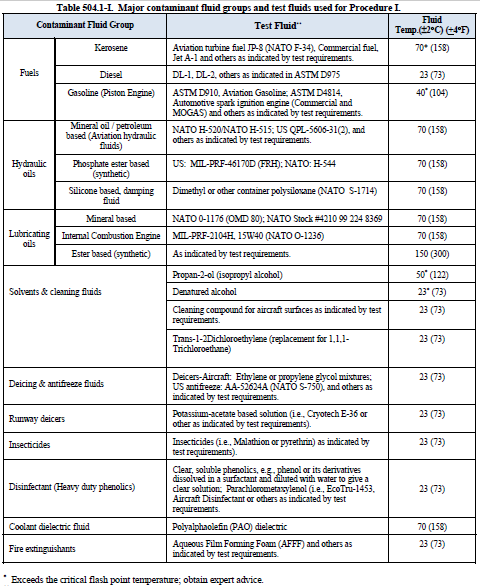

Procedure I - Large Systems. For materiel such as aircraft systems, full-up wheeled and track vehicles, and watercraft, to name a few, where operational temperatures may be critical. The most significant parameters used in this test procedure are the fluid(s) to be used, the temperature, and the duration of exposure. It is also important to specify the operational configuration of the test item, as well as whether or not the test item is a heat dissipating during operation.

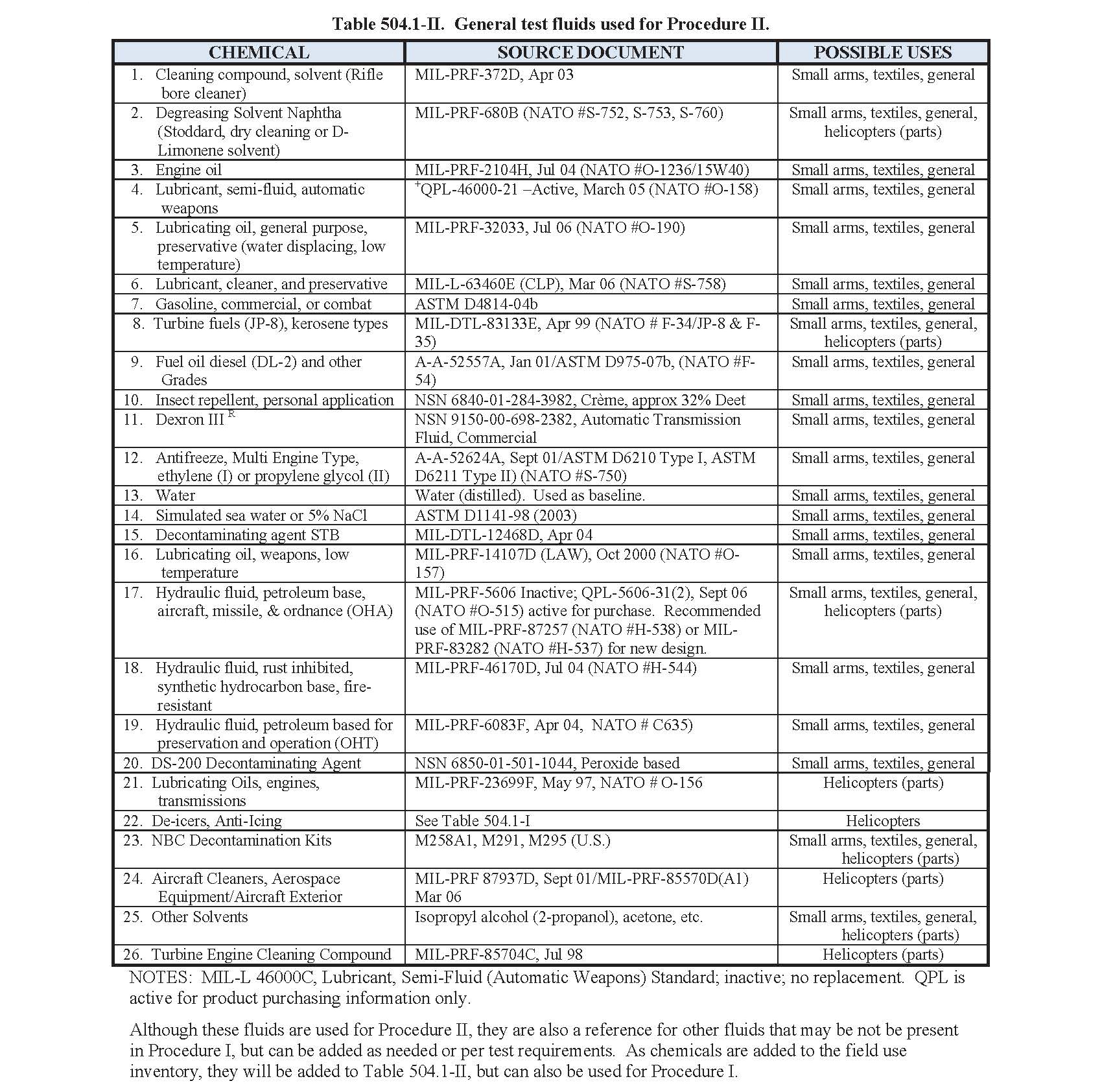

Procedure II – Small Systems. For materiel addresses the chemical compatibility of nonmetallic materials used in small arms systems, clothing, boots, gas masks, gloves, Less Than Lethal and other ammunition, binoculars, flashlights, small arms tripods, and another materiel. Testing is performed at standard ambient conditions, but this procedure is more tailorable in that the immersion times and item/solution temperatures can be changed to suit the test program.

Tips and Tricks;

- As a rule of thumb tailoring is essential. Meaning setting EUT test limits with the customer beforehand. Temperature limits are variable based upon the version of the standard. Test limits in this particular test are usually chosen from high or low operational temperature limits.

- Discuss EUT configuration with the customer. Prefer conditions for EUT most likely to be affected in real life. I.e. Storage, Packed, Unpack, Deployed, etc.

- Discuss with the customer;

•Test fluid(s) to be used and its temperature (see table above),

•Method of test fluid application (i.e. immersing, spraying, splashing, brushing, etc),

•Soak (post-wetting) temperature and duration,

•Cleaning/decontaminating fluids (during the test, if any: i.e. use of any tool),

•Type of exposure (i.e., occasional, intermittent, or extended)

- Set pass/fail criteria clearly with the customer; which operational features needed to be tested after storage or during tests. Prepare instructions for test laboratory experts step by step about how to test EUT. For example, some devices may be intended to be decomposed or deteriorate after fluid exposure, this may not be a failure criterion. Or in a scenario material paint may dissolve but a perfect operation of the device may pass the criteria.

DID YOU KNOW?

PALS Electronics has experts on all subjects of test engineering, mechanical or electronic design, environmental condition engineer, system engineer, etc. PALS provides consulting, training, tailoring, test plan, test engineering, test services in all phases of your project. Please feel free if you have any questions or inquiries from https://pals.com.tr/contact

by System Integration Engineer, Özdemir Öztürk