- 2022-02-18 15:19:52

Preface: This article is the 4th article that belongs to an article series. You may find the introduction article from following link: https://pals.com.tr/blog/environmental-test-engineering-and-pals-service-article-series-1

We will proceed to elaborate the “Methods” and “Procedure”s of environmental standards of MIL-STD-810 in our article series. Instead of writing down the obvious information already given in the standard, we will be discussing more practical information on product design, features regarding “Equipment Under Test” (EUT), and conducting tests.

Test Method 503.4 - Temperature Shock

This method uses a temperature shock test to determine if material can withstand sudden changes in the temperature of the surrounding atmosphere without experiencing physical damage or deterioration in performance. "sudden changes" is defined as "an air temperature change greater than 10°C (18°F) within one minute."This method uses a temperature shock test to determine if material can withstand sudden changes in the temperature of the surrounding atmosphere without experiencing physical damage or deterioration in performance. "sudden changes" is defined as "an air temperature change greater than 10°C (18°F) within one minute."

This method uses a temperature shock test to determine if material can withstand sudden changes in the temperature of the surrounding atmosphere without experiencing physical damage or deterioration in performance. "sudden changes" is defined as "an air temperature change greater than 10°C (18°F) within one minute."

This method uses a temperature shock test to determine if material can withstand sudden changes in the temperature of the surrounding atmosphere without experiencing physical damage or deterioration in performance. "sudden changes" is defined as "an air temperature change greater than 10°C (18°F) within one minute."

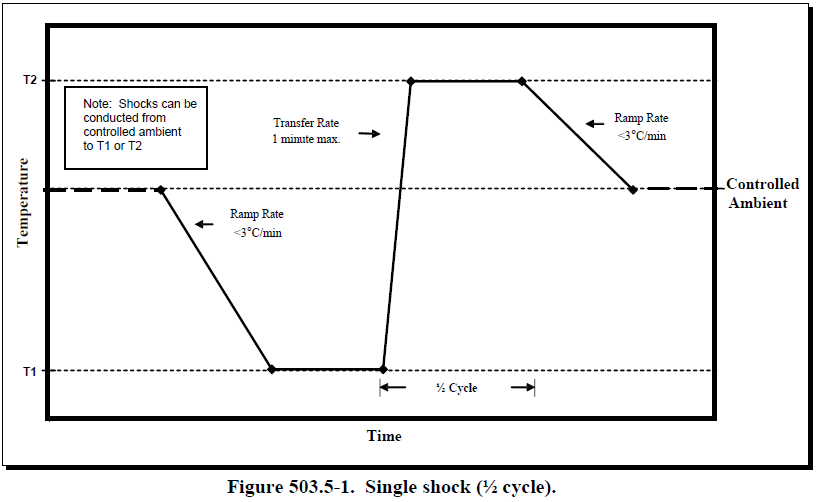

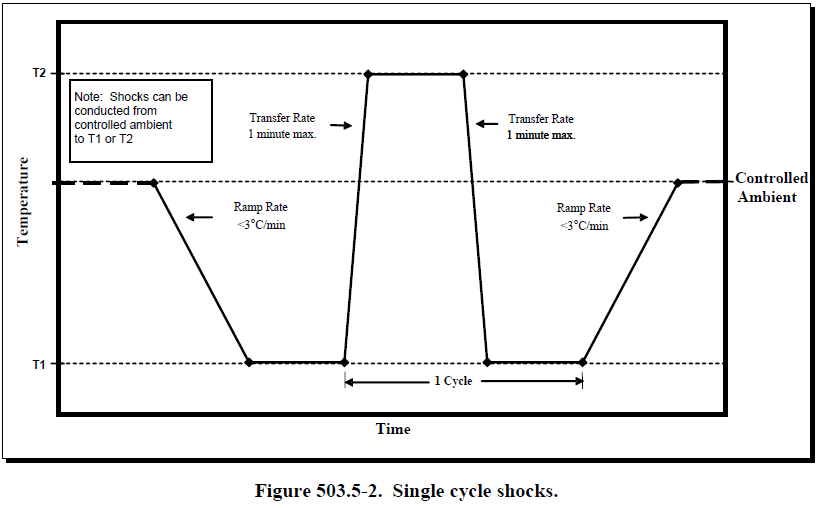

Procedure I-B. Single-cycle shock from constant extreme temperature. For materiel that is likely to be exposed to only one thermal shock cycle (one in each direction).

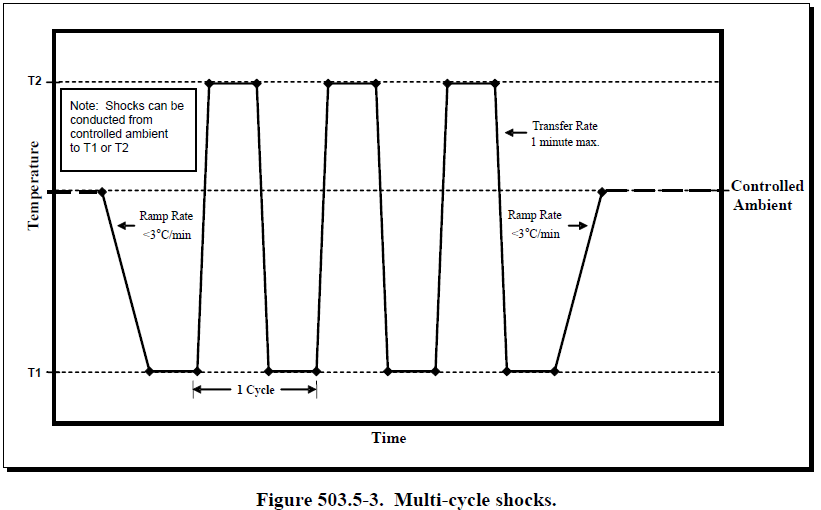

Procedure I-C. Multi-cycle shocks from constant extreme temperature.

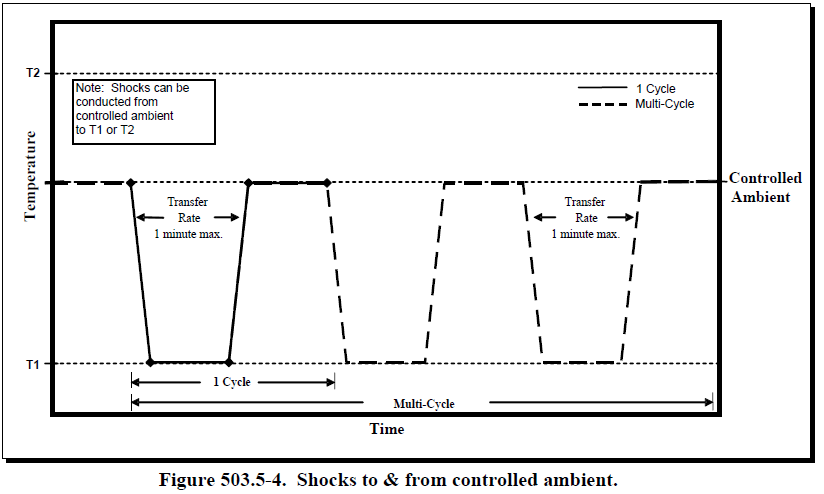

Procedure I-D. Shocks to or from the controlled ambient temperature.

Tips and Tricks;

-As a rule of thumb tailoring is essential. Meaning setting EUT test limits with the customer beforehand. Temperature limits are variable based upon the version of the standard. Test limits in this particular test are usually chosen from high or low storage temperature limits.

-Discuss EUT configuration with the customer. Prefer conditions for EUT most likely to be affected in real life. I.e. Storage, Packed, Unpack, Deployed, etc.

-Set pass/fail criteria clearly with the customer; which operational features needed to be tested after storage or during tests. Prepare instructions for test laboratory experts step by step about how to test EUT.

-Glass materiel will most likely break. Consider using tempered glass or if EUT also going to be tested for MIL-STD-461 EMI-EMC tests consider using EMI filtered composite material.

-Moving parts may bind or slacken after this test. Consider using proper lubricant for binding. Consider materiel expansion or shrinkage while in the design phase of a product.

-Humidity is not controlled during this test. Therefore rapid condensation of humid and water droplets may occur during this test. Not only outside of EUT also inside of it as well.

-PCB boards may fail because of water droplets. Consider using thermal paste for covering PCBs. Consider physically mounting PCBs away from the EUT bottom. I.e. Vertical.

-If the test consists of more than one cycle, these droplets may freeze over and over again inside EUT. Consider adding water drainage to the design to manipulate droplets.

DID YOU KNOW?

PALS Electronics has experts on all subjects of test engineering, mechanical or electronic design, environmental condition engineer, system engineer etc. PALS provides consulting, training, tailoring, test plan, test engineering, test services in all phases of your project. Please feel free if you have any questions or inquiries from: https://pals.com.tr/contact