- 2022-03-21 13:56:01

You may find the introduction article from following link:https://pals.com.tr/blog/environmental-test-engineering-and-pals-service-article-series-1

We will proceed to elaborate the “Methods” and “Procedure”s of environmental standards of MIL-STD-810 in our article series. Instead of writing down the obvious information already given in the standard, we will be discussing more practical information on product design, features regarding “Equipment Under Test” (EUT), and conducting tests.

Test Method 508.6 – Fungus

This method used to evaluate tests is to assess the extent to which material will support fungal growth and how any fungal growth may affect the performance or use of the material. The primary objectives of the fungus test are to determine:

a. if the materials comprising the materiel, or the assembled combination of same, will support fungal growth, and if so, of what species.

b. how rapidly fungus will grow on the material.

c. how fungus affects the material, its mission, and its safety for use following the growth of fungus on the material.

d. if the material can be stored effectively in a field environment.

e. if there are simple reversal processes, e.g., wiping off fungal growth.

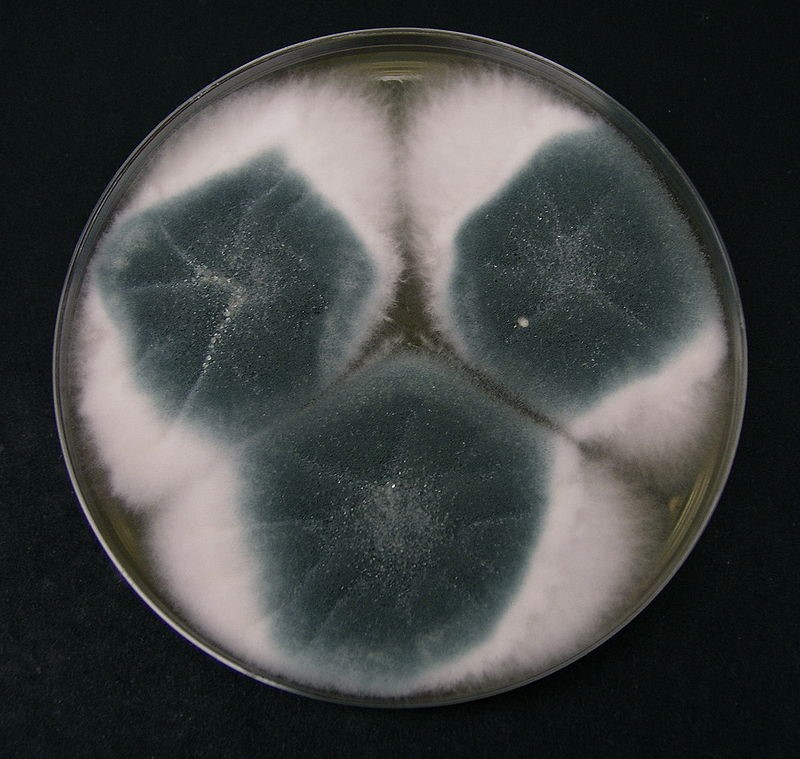

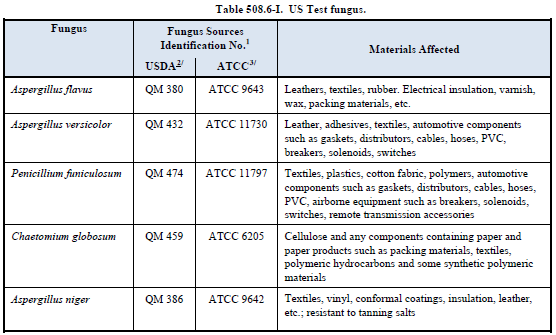

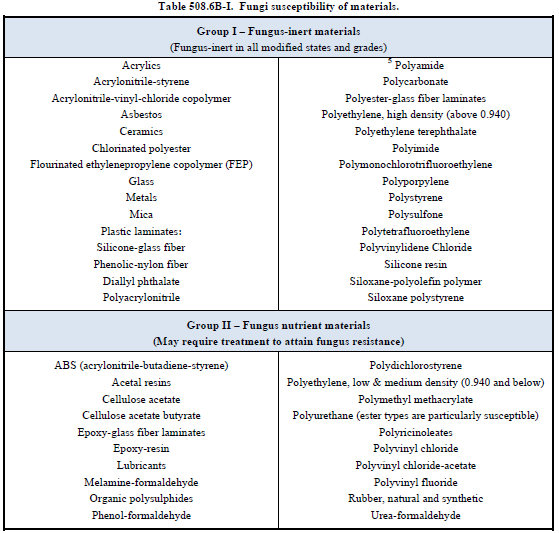

The fungi commonly used are listed in Table 508.6-I. These organisms were selected because of their ability to degrade materials, their worldwide distribution, and their stability. These organisms have, where possible, been identified concerning the materials to which they are known to attack.

Test Duration

Twenty-eight days is the minimum test period to allow for fungus germination, breakdown of carbon-containing molecules, and degradation of the material. Since indirect effects and physical interference are not likely to occur in the relatively short time frame of the fungus test, consider an extension of the exposure period up to 84 days if a greater degree of certainty (less risk) is required in determining the existence or effect of fungus growth.

Tips and Tricks;

• Fungus test is one of the most tailorings required tests among standard tests. Hence most tips will be referring to them.

• Determine fungus culture which will be used in the test. Keep in mind table given above is merely a suggestion. Standard suggests fungal selection by most commonly found fungi of the geographical deployment area of materiel. Standard dictates and I quote “The European species can be found in STANAG 4370, AECTP 308.” A cocktail of fungus culture containing more than one fungi is commonly used for this test.

• Some of the fungi don’t work very well together. They will be stressed about consuming nutrients present in the environment and try to overpopulate faster than competitive fungus. Hence may cause unnatural results. Also, some fungi produce byproducts that may affect others. For example, Saccharomyces Cerevisiae (a.k.a. common yeast used in food manufacture) consumes all kinds of glucose and produces alcohol, as we know it, and alcohol is poisonous for another fungus. Generally, 3-5 fungus type and/or separate execution of the test is suggested by the standard to prevent such incidents.

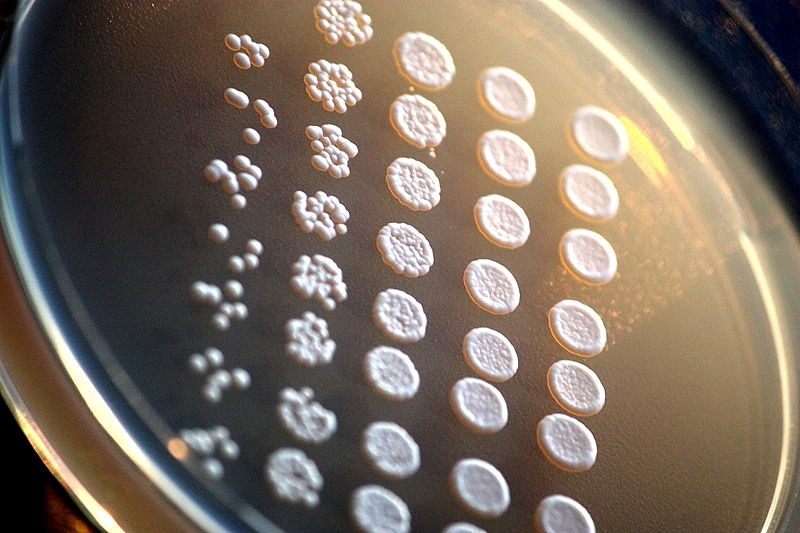

• Fungal or bacterial growth which does not include a fungal cocktail can be expected. The fungus can naturally exist on materiel before the test. I.e. human hands produce natural oil which contains many bacteria. Contamination may occur by simply touching the materiel.

• If cleaning, disinfecting material before the test is chosen, please keep in mind this is a configuration unit change in the aspect of configuration management and system engineering.Meaning it should be applied to all materials manufactured as well.

• Determine test duration according to fungus chosen. Test duration given above is a suggestion based upon the table given above as well. Although a minimum number of tests is clearly stated as 28 days is standard. This test is the longest time takes for execution amongst in standard.

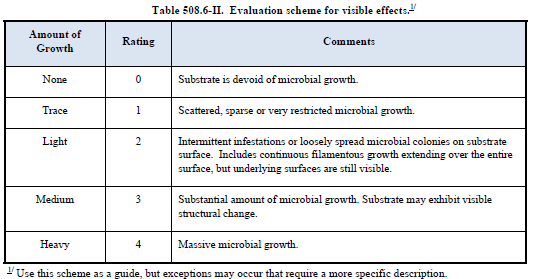

• Having analytical evaluation from this test requires a microbiologist expert. Standard suggests using the following table. Please note this is not a pass/fail criteria.

• Using a deterministic method for setting pass/fail criteria is encouraged. The table given above can be helpful guidance. Although having nonfungal growth should be past criteria that come to mind first, keep in mind this target may be unrealistic. Instead setting scientific pass criteria such as 3 fungal colonies rated 2, 5 scatters rated 1, etc would be more realistic. Another example of pass/fail criteria, for non-edible materiel, maybe: having target operational mission completed or no structural change can be applied as well.

• Study target fungus. Simply fungus needs nutrients to exist. Design not using such materiel to prevent fungal growth. I.e. choosing synthetic lubricant instead of organic. A table is given in standard as well as below as a suggestion for such purpose.

DID YOU KNOW?

PALS Electronics has experts on all subjects of test engineering, mechanical or electronic design, environmental condition engineer, system engineer, etc. PALS provides consulting, training, tailoring, test plan, test engineering, test services in all phases of your project. Please feel free if you have any questions or inquiries from https://pals.com.tr/contact